Hamish Mackie – About Me And What I Do

Description

About Hamish Mackie

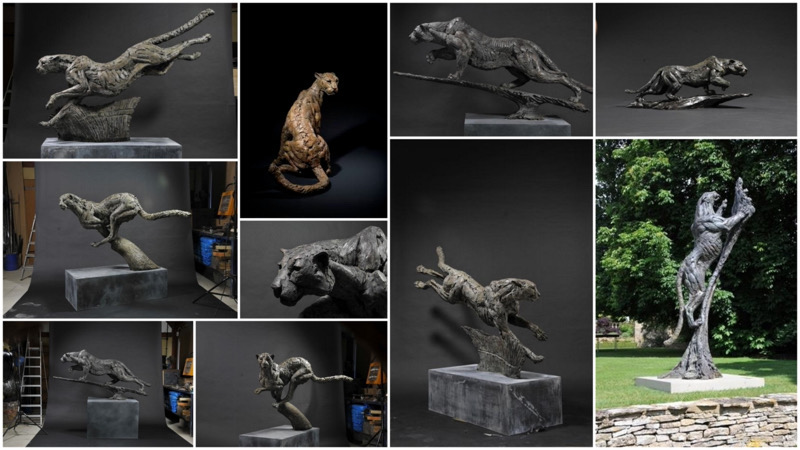

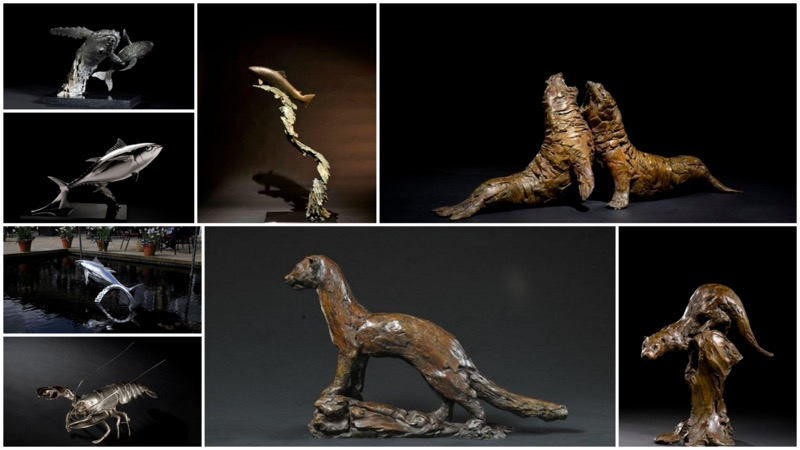

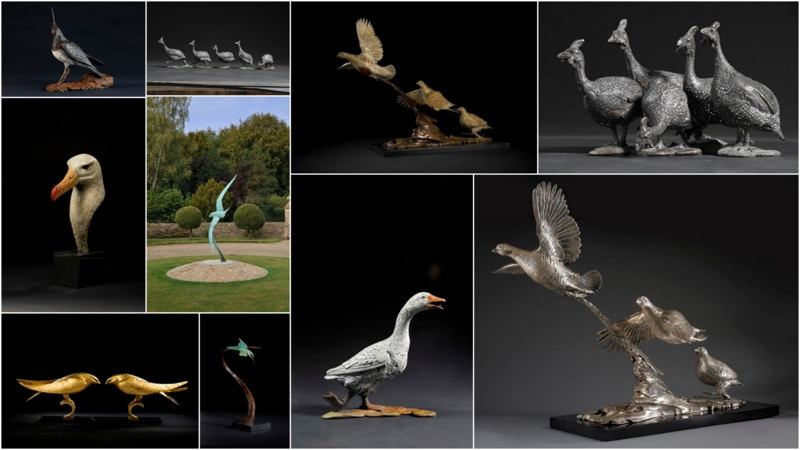

Through his work as a sculptor Hamish Mackie has had the privilege of observing wildlife in many corners of the world at first hand, thus bringing his passion for the natural world into his sculptures. Largely self-taught, Hamish’s style is unique; his work captures the inner core, strength, and grace of the subject. His sculptures are his own interpretation, and not a photographic representation of the subject, through his close observation and his expressive manipulation of the materials Hamish is able to capture an instinctive moment of animal behaviour.

Hamish frequently works in spontaneous, often unrepeatable, fluid gestures. This confidence is born from many years of mastering his craft. It is this assertive handling of materials, which result in strong dynamic, living sculpture. However his sculpting ‘technique’ will vary according to how he perceives the subject; for example, a compact feathered bird such as an albatross will be sculpted in a tight method, in comparison to the free feathers of an owl that dictate a looser handling.

‘…standing at the end of a very long process of development.’ Hamish’s sculpture is clearly informed by the works of the ancient Egyptians and the Renaissance, through to the more recent realism and drama of Barye and Buggatti.

Born in 1973, Hamish grew up on a livestock farm in Cornwall, England. He developed a love of wildlife at an early age. After Radley College, Falmouth School of Art and studying design at Kingston University, it was in 1996 that Hamish began sculpting full time, thus turning his passions into a career. In 2007 Hamish built a studio in Oxfordshire, where he now lives and works with his wife Laura and their three daughters Isabella, Matilda and Otterlie.

Since his last London solo exhibition in 2010, Hamish has travelled to Antarctica, the Falkland Islands, South Georgia, Africa and United Arab Emirates to study his subjects. “Observing animals in their own environment is essential to understanding the subject’s physical and instinctive traits. For example, the disposition of a captive leopard is very different from that of a leopard in the wild.”

Bronze Casting

At a time when contemporary art is criticised for lacking craft, bronze casting is a refreshing antidote. Each sculpture takes on average four months to be sculpted, moulded and then cast into bronze. It is a highly skilled, labour-intensive process. Hamish’s sculptures are cast in England by the Lockbund Sculpture Foundry. He has a 20-year history of working with this foundry building a crucial relationship between sculptor and founder; together rising to various technical challenges, from casting intricate feather detail to a life-size cheetah supported on one leg.

Whatever the sculpture, the finish is always of museum quality. ‘You sculpt what you want and we’ll work out how to cast it.’ Simon Allison – Lockbund Sculpture Foundry.

“I love the fact that a finger print left in the clay original comes through into the bronze. I take full advantage of the technical capabilities of a good foundry.”

Bronze’s tensile strength allows compositions with minimal supports, unthinkable in materials such as marble, wax and plaster from which sculptures are initially created. This results in tactile bronze sculptures that will last many centuries.

Bronzes are made by pouring molten bronze into a ceramic investment – known as the ‘Cire Perdue’ or ‘Lost wax’ Method. The same technique dates back 5000 years. The skill of transforming one material into another is to preserve all of the detail of the original.

Positive original to negative mould

The first stage of making a bronze is to sculpt the original. Hamish uses different materials such as clay, plasticine or wax, depending on where and what he is sculpting. This is built up over a steel and aluminium anatomical skeleton known as an armature. A silicon rubber mould is made over the original. The soft silicon rubber forms an exact negative of the positive original held in the right shape by a rigid fiberglass outer case. Multi-section moulds fit together with millimetre precision.

Negative mould to positive wax

Molten wax is slushed into the mould, poured out and the remaining skin allowed to cool; this forms a hollow wax positive approximately 4mm thick. The seam lines where the mould sections fitted together are then worked out and the sculpture cut up into castable sections. To this a series of wax pipes called runners and risers are fitted (known as sprues); these allow the molten bronze to flow in and the gases to come out. Each time an edition is cast another wax has to be made.

Positive wax to negative ceramic investment

The ‘sprued up’ wax is then coated inside and out with liquid ceramic and grit, built up in layers to form a strong heat-resistant investment around the wax. This is then baked upside down in an oven, allowing the wax to be burnt out – hence the term ‘Cire Perdue’ or ‘lost wax’.

Negative ceramic investment to positive bronze

The negative space formerly occupied by the wax is now filled with molten bronze poured in at 1200ºC into the pre-heated ceramic investment. Other metals such as silver can be cast using the same method but at different temperatures.

When the bronze has cooled, the ceramic shell is painstakingly hammered away and the sprues cut off. To remove the hard ceramic from the surface detail and deep undercuts, the bronze is placed in acid, which further breaks down the investment.

Chasing

If the bronze has been cast in several pieces, it is now welded together and chased. This is a highly skilled process recreating any surface detail. “It’s easy for me to push my fingers into soft wet clay, not so easy to reproduce in hard metal; the sign of a quality casting is not to notice the chasing.” If structurally necessary, sculptures are fitted internally with stainless steel supports.

Patinating

The sculpture is now ready to be heated up and applied with a wide range of chemicals, which form the finished patina. Hamish is one of few sculptors who do their own patination, as he considers this to be as important as the colour of paint on a canvas.

Exhibitions

Please contact Hamish to arrange to view a sculpture or to be added to his mailing list

Past exhibitions include:

Third Major Solo show

The Gallery in Cork Street, LondonSoane, Pimlico Road, London

Art London

Art in Action

Ainscough Contemporary Art,

Drayton Gardens, London

The Royal Academy Summer Exhibition, London

The Tryon Gallery, London.

The CLA Game Fair (With Brewin Dolphin)

Fine Art Commissions, London.

Rathbones, Edinburgh.

Knight Frank, Hungerford.

The Game Conservancy Trust

Hunting exhibition organised by the Royal Saint-Hubert

Club of Belgium

The Wykham Gallery, Stockbridge Hampshire.

Collier and Dobson

2004 Solo Show, The Gallery in Cork Street, London

2007 Solo Show, The Gallery in Cork Street, London

Commissions Include

Merrill Lynch, London

Hiscox, London

Andrew Winch Design

Horse and Hound Blenheim Trophy

Countryside Alliance

Lewa Downs, Kenya

Chippenham Park, Cambridgeshire

Knowsley Park, Derbyshire

Tregothnan Estates, Cornwall

Trewithen Estates, Cornwall

Cadogan Estates, Scotland

Little Haugh Hall, Suffolk

Clear Water, Nova Scotia, Canada

Radley College

Jilly Cooper

Charles Saatchi

Sir Dominic Cadbury

Sir Anthony Bamford

Dame Vivian Duffield

Ronnie Wood

The National Trust

Archerfield links

Barclays Private Bank Ltd

National Trust

RSPCA The Marina Arnsbry award

Woburn Abbey

Calcot Manor

Kifu the Gorilla, Howletts

Chapman University, California

Gilbane Development Company, Rhode Island

Daylesford Organic, London

Chalky, Rick Stein

Bahamas Development Company, Bahamas

Alibaba Group, Hong Kong

The Lucas Collection, Los Angeles